Pneutork Electrical Actuator operated upvc ball valve made with precision turning and grinding to ensure that it’s true round less and smoothness is achieved. This provides for lower torque requirement and ease of handling. True union design provides for tight shut-off. These valves are most suited for water treatment and chlorination applications. The socket and screwed joint available.

1/2” TO 4”

| Working Pressure | 7Kg/Cm2 |

|---|---|

| Working Temperature | Upto 80ºC Max. |

| Ends | Screwed / Socket weld end |

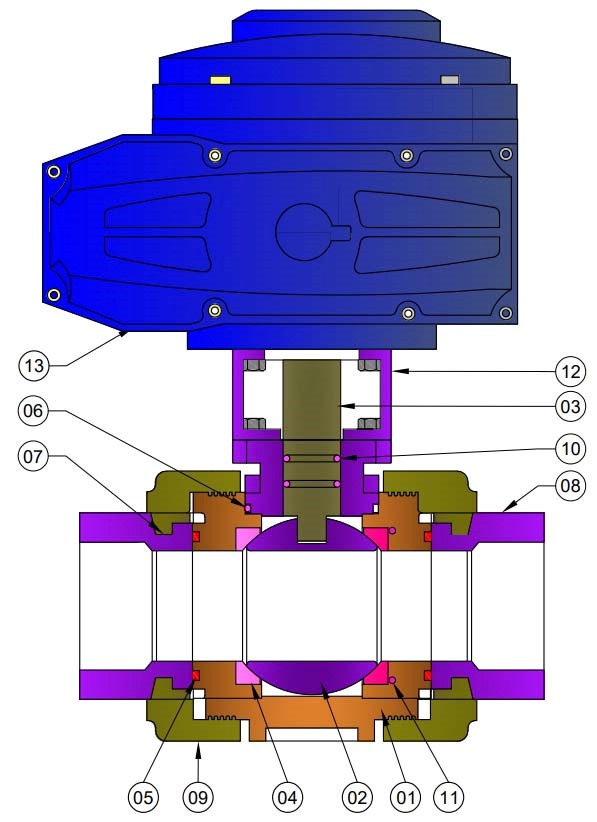

| No. | Description | Material | QTY |

|---|---|---|---|

| 1 | Body | UPVC | 01 |

| 2 | Ball | UPVC | 01 |

| 3 | Stem | UPVC | 01 |

| 4 | Ball Seat | PTFE/EPDM/VITON | 02 |

| 5 | Body O ring Left | NBR | 02 |

| 6 | Body Connector O ring | NBR | 01 |

| 7 | Body Connector Left | UPVC | 01 |

| 8 | Body Connector Right | UPVC | 02 |

| 9 | Connector Nut | UPVC | 02 |

| 10 | Stem O ring | NBR | 01 |

| 11 | Body O ring Right | NBR | 01 |

| 12 | Bracket | CF8/CF8M | 01 |

| 13 | Actuator | STD. | 01 |

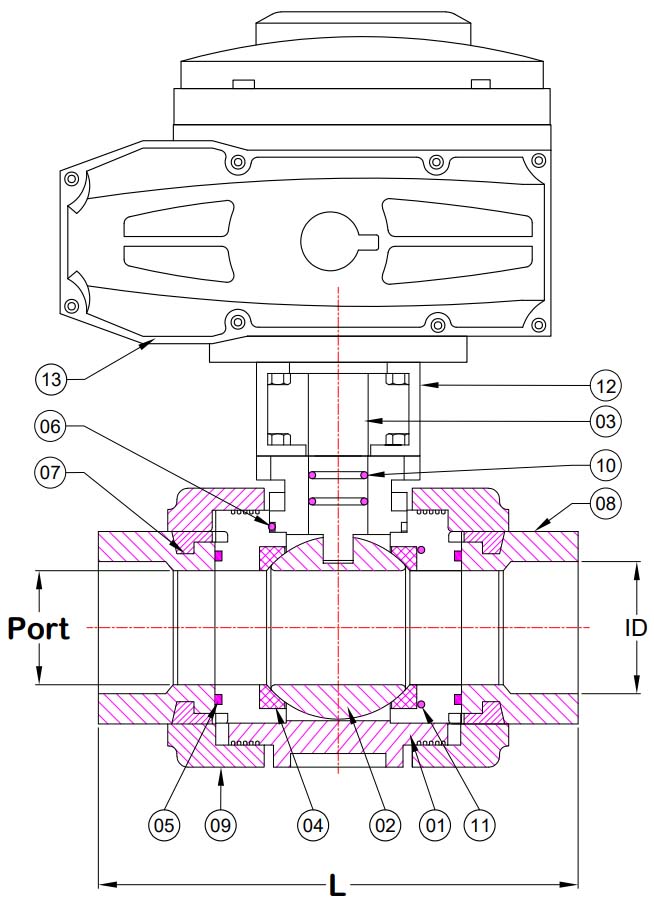

| Valve Size | ||||

|---|---|---|---|---|

| MM | Inch | L | ID | PORT |

| 15 | 1/2" | 108.50 | 21.23 | 15 |

| 20 | 3/4" | 114.50 | 26.57 | 20 |

| 25 | 1" | 128 | 33.27 | 25 |

| 32 | 1.1/4" | 142 | 42 | 32 |

| 40 | 1/1/2" | 160 | 48 | 40 |

| 50 | 2" | 174 | 60.17 | 50 |

| 65 | 2.1/2 | 241 | 72.85 | 63 |

| 80 | 3" | 270 | 270 | 75 |

Reach out for tailored solutions. Our team is ready to assist. Submit an inquiry and experience excellence in valve automation solutions.