"PHQ" series electric actuator is used for controlling 0°~270° rotation of the valves and other similar products, such as butterfly valve, ball valve, damper, flapper valve, cock valve etc. It widely applies to petroleum, chemical, water treatment, shipping, paper making, power plant, heating, light industry and other industries. Drived by 380V/220V/110VAC power or 24V/110VDC power, inputs 4-20mA or 0-10VDC control signal, moves valve to the right position, and achieves to automatic control, maximum output torque is 6000N·M.

The shell is made of aluminum alloy, with anodic oxidation treatment and polyester powder coating. It is strong corrosion-resistant and enclosure Ip67, NEMA 4 and 6, IP68 and explosion-proof is optional.

Asynchronous motor, small, large torque, and small inertia force, F-class insulation rating, with thermal protection to avoid damaging.

The design of handwheel is safe, reliable, labor-saving, small. Declutch to operate by handwheel if without power, and reset automatically when power on.

Installs indicator in the center axis and adopts convex mirror design, no cumulate water, more convenient to observe.

It is used for controlling temperature to avoid condensing internal of housing and keep dry

Mechanical, electronic double limit. Mechanical limit stopper is adjustable, safe and reliable; electronic limit switch is controlled by cam. Set position accurately and conveniently, and not affected by excessive handle.

(Except OHQ-005/008/010) Providing overload protection to avoid the damage of valve and electric actuator when jammed by cutting power automatically.

Accurate worm and worm gear transfer large torque efficiently, high efficiency, low noise (max. 50 dB), long life, with self-locking, prevent inversion, as stable and reliable transmission parts, no need to refuel.

The installation size meets international standard ISO5211 / DIN3337.

Controlling circuit meets the single-phase or three-phase power supply standard, circuit layout is reasonable and compact, terminals meet various of additional functional requirements effectively.

During the opening or closing movement of actuator, the change of valve position on LCD is displayed with large numbers

| Actuator Model | Max Output Torque | 60/50Hz Operating Time | Max Drive Shaft Size | Power | Rated Current (A) | Hand wheel Revolution | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|

| N-M | 90° | mm | W | 110V Single Phase | 220V Single Phase | 380V Three Phases | 440V Three Phases | N | Kg | |

| PHQ-005 | 50 | 18/22 | Φ20 | 20 | 1.10/0.95 | 0.55/0.54 | 0.3/0.3 | 10 | 7.5 | |

| PHQ-008 | 80 | 18/22 | Φ20 | 20 | 1.10/0.95 | 0.55/0.54 | 0.3/0.3 | 10 | 7.5 | |

| PHQ-010 | 100 | 18/22 | Φ20 | 20 | 1.10/0.95 | 0.55/0.54 | 0.3/0.3 | 10 | 7.5 | |

| PHQ-015 | 150 | 21/25 | Φ22 | 40 | 1.65/1.67 | 0.88/0.84 | 0.31/0.31 | 0.30/0.31 | 11 | 17.3 |

| PHQ-020 | 200 | 21/25 | Φ22 | 40 | 1.65/1.67 | 0.88/0.84 | 0.31/0.31 | 0.30/0.31 | 11 | 17.3 |

| PHQ-030 | 300 | 26/31 | Φ35 | 90 | 1.85/1.86 | 0.92/0.92 | 0.51/0.50 | 0.45/0.46 | 13.5 | 22 |

| PHQ-050 | 500 | 26/31 | Φ35 | 90 | 3.60/3.62 | 1.55/1.58 | 0.59/0.59 | 0.58/0.58 | 13.5 | 23 |

| PHQ-060 | 600 | 26/31 | Φ35 | 90 | 3.65/3.62 | 1.60/2.20 | 0.60/0.60 | 0.58/0.58 | 13.5 | 23 |

| PHQ-080 | 800 | 31/37 | Φ45 | 180 | 4.10/4.10 | 2.15/2.20 | 0.85/0.85 | 0.79/0.79 | 16.5 | 29 |

| PHQ-120 | 1200 | 31/37 | Φ45 | 180 | 4.10/4.10 | 2.15/2.20 | 0.85/0.85 | 0.79/0.79 | 16.5 | 29 |

| PHQ-150 | 1500 | 78/93 | Φ45 | 180 | 3.65/3.62 | 1.60/2.20 | 0.59/0.59 | 0.58/0.58 | 40.5 | 77 |

| PHQ-200 | 2000 | 93/112 | Φ45 | 180 | 4.10/4.10 | 2.15/2.20 | 0.85/0.85 | 0.79/0.79 | 49.5 | 83 |

| PHQ-300 | 3000 | 93/112 | Φ45 | 180 | 4.10/4.10 | 2.35/2.20 | 0.87/0.87 | 0.81/0.81 | 49.5 | 83 |

| PHQ-400 | 4000 | 155/185 | Φ45 | 180 | 4.20/4.10 | 2.35/2.30 | 0.87/0.87 | 0.81/0.81 | 82.5 | 83 |

| PHQ-500 | 5000 | 155/185 | Φ45 | 180 | 4.20/4.10 | 2.35/2.30 | 0.87/0.87 | 0.81/0.81 | 82.5 | 83 |

| PHQ-600 | 6000 | 155/185 | Φ45 | 180 | 4.20/4.10 | 2.35/2.30 | 0.87/0.87 | 0.81/0.81 | 82.5 | 83 |

| No. | Option scheme | Remark |

|---|---|---|

| 1 | Explosion-proof actuator(Exd ⅡCT5) | PHQ series |

| 2 | Water-proof actuator (IP68, 10M, 250HR) | PHQ series |

| 3 | Potentiometer unit(1K-10K) | PHQ series |

| 4 | Proportion control unit (control signal 4-20mA DC/1-5V/1-10V) | PHQ series |

| 5 | Local control units (local control open/stop/close optional switch, local/remote switch) | PHQ series |

| 6 | Travel 120°, 180°, 270° | PHQ series |

| 7 | Direct current motor (24VDC) | PHQ series |

| 8 | Torque switch (SPDT× 2 250VAC 10A) | Except PHQ-005/008/010 |

| 9 | Electric current position sensor (output 4-20mA DC) | PHQ series |

| 10 | Self-reset when power failure | PHQ series |

| 11 | High temperature resistance actuator (-10℃~+100℃) | PHQ series |

| 12 | Low temperature resistance actuator (-40℃~+70℃) | PHQ series |

| 13 | Low speed actuator | PHQ series |

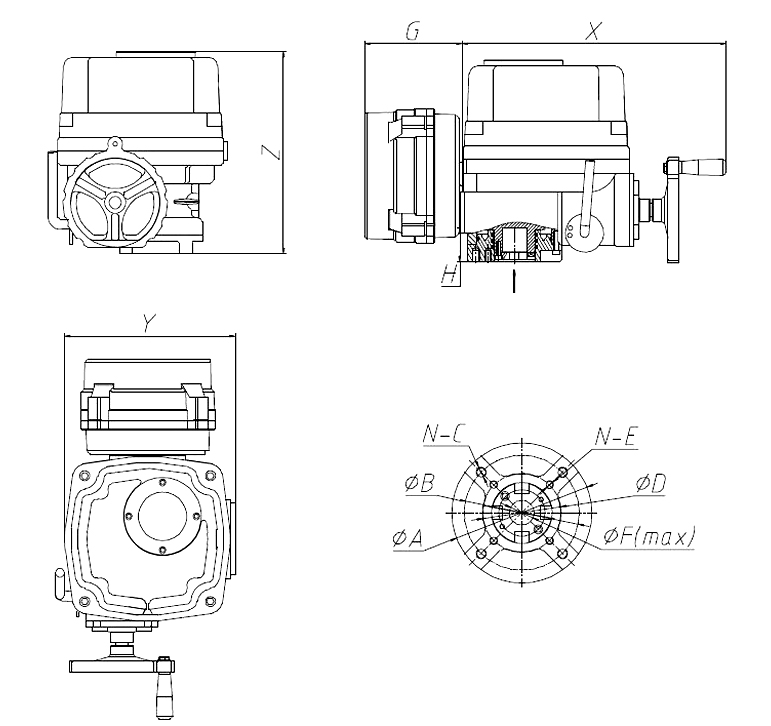

| Model | X | Y | Z | ΦA | ΦB | N-C | ΦD | N-E | ΦF | G | H |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PHQ-005 | 26 | 161 | 236 | Φ90 | Φ70 | 4-M8 | - | - | Φ20 | 140 | 40 |

| PHQ-008 | 260 | 161 | 236 | Φ90 | Φ70 | 4-M8 | - | - | Φ20 | 140 | 40 |

| PHQ-010 | 260 | 161 | 236 | Φ90 | Φ70 | 4-M8 | - | - | Φ20 | 140 | 40 |

| PHQ-015 | 351 | 227 | 270 | Φ125 | Φ102 | 4-M10 | Φ70 | 4-M8 | Φ22 | 140 | 45 |

| PHQ-020 | 351 | 227 | 270 | Φ125 | Φ102 | 4-M10 | Φ70 | 4-M8 | Φ22 | 140 | 45 |

| PHQ-030 | 367 | 242 | 290 | Φ150 | Φ125 | 4-M12 | Φ102 | 4-M10 | Φ35 | 140 | 55 |

| PHQ-050 | 367 | 242 | 290 | Φ150 | Φ125 | 4-M12 | Φ102 | 4-M10 | Φ35 | 140 | 55 |

| PHQ-060 | 367 | 242 | 290 | Φ150 | Φ125 | 4-M12 | Φ102 | 4-M10 | Φ35 | 140 | 55 |

| PHQ-080 | 410 | 276 | 330 | Φ180 | Φ140 | 4-M16 | Φ140 | 4-M12 | Φ45 | 140 | 65 |

| PHQ-120 | 410 | 276 | 330 | Φ180 | Φ140 | 4-M16 | Φ140 | 4-M12 | Φ45 | 140 | 65 |

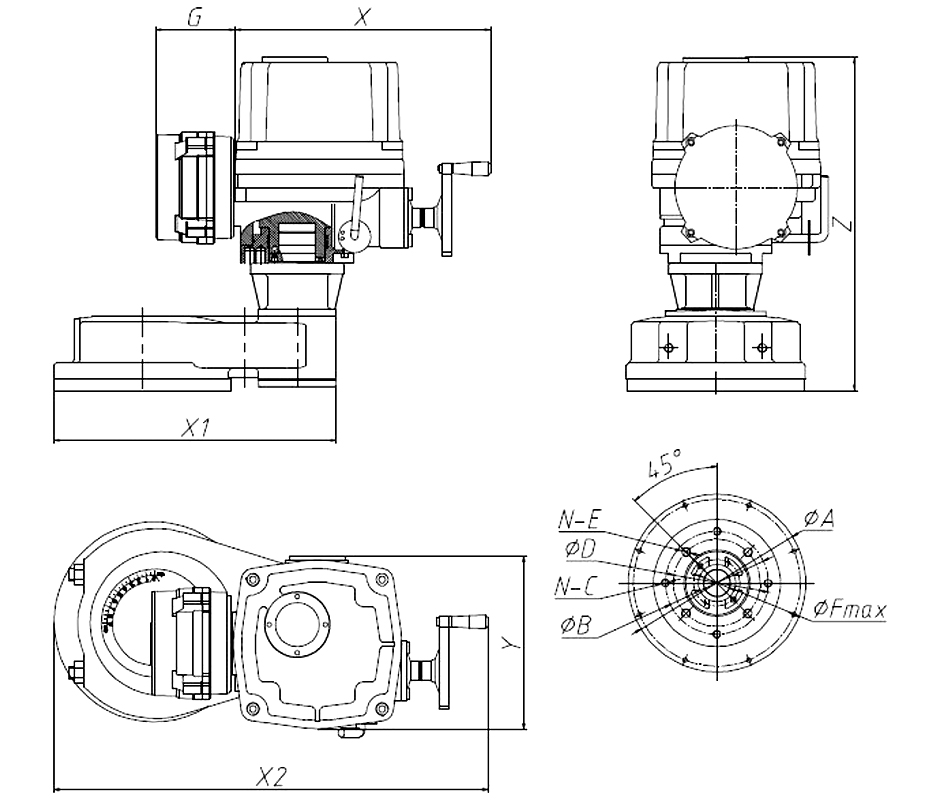

| Model | X | Y | Z | ΦA | ΦB | N-C | ΦD | N-E | ΦF | G | X1 | X2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PHQ-150 | 410 | 276 | 330 | Φ285 | Φ165 | 4-M18 | Φ140 | 4-M16 | Φ45 | 140 | 454 | 696 |

| PHQ-200 | 410 | 276 | 330 | Φ285 | Φ165 | 4-M18 | Φ140 | 4-M16 | Φ45 | 140 | 454 | 696 |

| PHQ-300 | 410 | 276 | 330 | Φ285 | Φ165 | 4-M18 | Φ140 | 4-M16 | Φ45 | 140 | 454 | 696 |

| PHQ-400 | 410 | 276 | 330 | Φ285 | Φ165 | 4-M18 | Φ140 | 4-M16 | Φ45 | 140 | 454 | 696 |

| PHQ-500 | 410 | 276 | 330 | Φ285 | Φ165 | 4-M18 | Φ140 | 4-M16 | Φ45 | 140 | 454 | 696 |

| PHQ-600 | 410 | 276 | 330 | Φ285 | Φ165 | 4-M18 | Φ140 | 4-M16 | Φ45 | 140 | 454 | 696 |

| Shell | Enclosure :IP67,NEMA4, Exd II Ct5 |

|---|---|

| Power |

Standard:220VAC/1ph

Optional:110VAC/1ph, 380V/440V/3ph, 50/60Hz, ±10% 24VDC/110VDC/220VDC |

| Motor | Asynchronous motor |

| Limit switch | 2×Open/ Close, SPDT,250VAC 10A |

| Auxiliary limit switch | 2×Open/ Close, SPDT,250VAC 10A |

| Torque switch | Close/Open, each 1, SPDT,250VAC 10A Except OHQ-005/008/010 |

| Travel | 90°±10° 0°~270° |

| Fail safe/Operating temperature | Internal-placed thermal protection, Open 115℃ ±5℃/Close 97℃ ± 5℃ |

| Indicator | Continuous position indicator |

| Manual operate | Declutching mechanism, operate by handwheel |

| Self-locking device | Self-locking by worm and worm gear |

| Mechanical limit | 2 × external adjustable stopper |

| Space heater | 30W(110V/220VAC) |

| Conduit entry | 32 × PF 3/4” |

| Ambient temperature | -20℃~+70℃ |

| Lubrication | Grease moly(EP type) |

| Material | 3Steel, Aluminum alloy, Aluminum bronze, Polycarbonate |

| Ambient humidity | Max 90% RH Non-Condensing |

| Anti-vibration | X Y Z 10g, 0.2~34 Hz, 30 minutes |

| External coating | Dry powder, Epoxy polyester, high anti-corrosion |

| Housing | including shell and base |

|---|---|

| Drive parts | asynchronous motor |

| Driving mechanism | double worm and clutch |

| Ratio control parts | separate with the mechanical parts, easy to debug |

| Torque switch and limit switch parts | |

| Opening detected and feedback parts. |

Reach out for tailored solutions. Our team is ready to assist. Submit an inquiry and experience excellence in valve automation solutions.