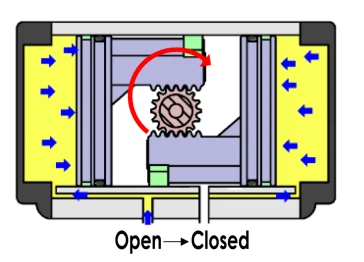

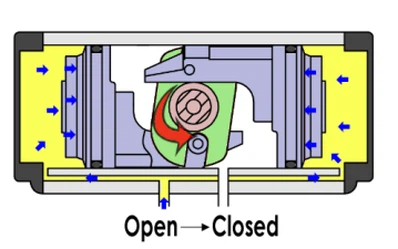

A rack and pinion actuator is a linear actuator that converts rotary motion into linear motion using a gear rack and a pinion gear. It is commonly utilized in various applications including automotive steering systems and industrial automation.On the other hand, a scotch yoke actuator is another type of linear actuator that converts rotary motion into linear motion using a slotted arm, also known as a yoke, and a piston. This type of actuator is typically employed in valves and pumps. Although both actuators accomplish the task of converting rotary motion to linear motion, they differ in their operational mechanisms. Rack and pinion actuators rely on a gear rack and pinion gear, while scotch yoke actuators use a slotted arm and a piston. The choice between these actuators depends on specific application requirements and desired performance characteristics.In general, rack and pinion actuators are more compact and occupy less installation space, while scotch yoke actuators offer greater torque and travel efficiency.

| Parameter | Scotch Yoke | Rack & Pinion | Comments |

| Cost | Lower | Higher | |

| Torque | Higher | Lower | |

| Lifecycle | 1 Million+ | 1 Million+ | |

| Frame size | Slightly longer | Slightly shorter | |

| Torque as function of Stroke | Non-Linear | Constant | The Scotch York torque curve provides a perfect match for butterfly valves. |

| Positioning(Throttling)Application | no | yes | For positioning applications, the Rack & Pinion Constant Torque Curve offers an optimal match. |

| Available in Spring Return(SR) or Double Acting(DA) | yes | yes | |

| Retrofittable between SR & DA | no | yes |

Rack & Pinion Working Diagram

Scotch Yoke Working Diagram

Pneutork Valve Automation offers a comprehensive selection of actuated valves, actuators, and associated accessories. For any inquiries or questions regarding these products, please feel free to contact us at: pneutork@gmail.com