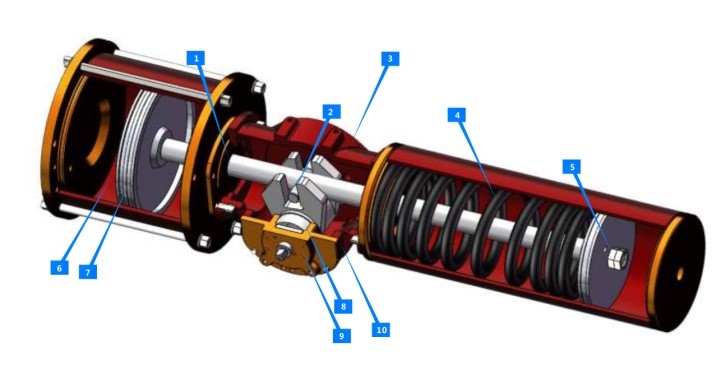

K Series Skotch Yoke Atuators Have Functional Modules Such As Pneumatic Actuator, Hydraulic Power, Sprin Power And Manual Control. All The Functional Modules Are Subject To Inter-Combination And Exchange, So That User Can Choose Various Modules According To Funtional Requirements Of Valve Process Control Procedure. Tha Modules Can Be Purchased Separately, Reducing Inventory Of Spare Parts.

K-Series Pre-Assembled Spring Module Adopts The Latest Manufacturing Process. It Preassembles A Spring In The Modules. Eliminating The Spring Of Incidental Release, Removing Potential Risks, Preventing Malfunction And Faciliating Desassmbly And Installation.

K-Series Actuators Integrate And Optimize The Center-Of-Gravity Position, Making The Appearance More Reasonable And Light. Compared With Other Actuators With The Same Torque, It Is Lighter And Need Less Installation Space.

Complying With Ip66 And Ip67 Protection Standards, All Parts And Components Are Equipped With O Rings At Their Joints, Which Can Effectively Prevent Water Entering The Case. It Is Able To Withstand Short-Term Or Long Term Immersion In Water, So That Users Can Make A Choice According To Requirments.

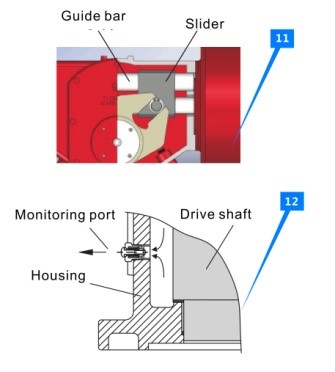

The Position Where The Piston Rod And Piston Slide And Rub Is Furnished With Self-Lubricating Bearing. The Piston Rod Is Plated With Hard Chrome And Is Provided With Fine Grinding And Finishing. The Cylinder Inner Wall Is Coated With Fine Grinding By Hard Chromium Plating. With Such Outstanding To The Valve, Which Reduces Friction And Effectively Improves The Utilization Efficiency Of Springs.

K-Series Actuators, With Internal Protection And External Coating, Are Reliably Application To All Kinds Of Environments And Are In Compliance With Relevant National Standards.

The Connection Size Of The Top Drive Shafts Of All K-Series Models Is The Same And Is In Compliance With Namur Standard, So That It Is Easy To Install Such Fittings As Position Switch, Locator. Valve Installation As For The Installation Of K-Series Actuators And Valves, Flanges And Shaft Key Connection, The Size Complies With The Torque Range Specified Iso 5211 Standards.

| MODEL | SPRING TORQUE | AIR SUPPLY PRESSURE | ||||||||

| 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 | ||

| K1-P200-DA | OPEN/CLOSED | 823 | 960 | 1097 | 1234 | 1372 | 1509 | 1646 | 1920 | 2195 |

| K1-P200-DA | MIN | 434 | 507 | 579 | 652 | 724 | 796 | 869 | 1014 | 1158 |

| K2-P250-DA | OPEN/CLOSED | 1576 | 1839 | 2101 | 2364 | 2627 | 2889 | 3152 | 3677 | 4203 |

| K2-P250-DA | MIN | 832 | 971 | 1109 | 1248 | 1386 | 1525 | 1664 | 1941 | 2218 |

| K3-P300-DA | OPEN/CLOSED | 2769 | 3231 | 3692 | 4154 | 4615 | 5077 | 5539 | 6462 | 7385 |

| K3-P300-DA | MIN | 1462 | 1705 | 1949 | 2193 | 2436 | 2680 | 2923 | 3411 | 3898 |

| K4-P350-DA | OPEN/CLOSED | 4533 | 5288 | 6044 | 6799 | 7555 | 8310 | 9066 | 10577 | 12088 |

| K4-P350-DA | MIN | 2393 | 2791 | 3190 | 3589 | 3988 | 4386 | 4785 | 5583 | 6380 |

| K5-P400-DA | OPEN/CLOSED | 5949 | 6941 | 7932 | 8924 | 9916 | 10907 | 11899 | 13882 | 15865 |

| K5-P400-DA | MIN | 3140 | 3664 | 4187 | 4710 | 5234 | 5757 | 6281 | 7327 | 8374 |

| K6-P500-DA | OPEN/CLOSED | 11468 | 13379 | 15291 | 17202 | 19113 | 21025 | 22936 | 26759 | 30581 |

| K6-P500-DA | MIN | 6053 | 7062 | 8071 | 9080 | 10089 | 11098 | 12107 | 14124 | 16142 |

| K7-P600-DA | OPEN/CLOSED | 21006 | 24507 | 28008 | 31509 | 35010 | 38512 | 42013 | 49015 | 56017 |

| K7-P600-DA | MIN | 11088 | 12936 | 14784 | 16632 | 18480 | 20328 | 22176 | 25872 | 29568 |

| K8-P700-DA | OPEN/CLOSED | 28646 | 33419 | 38193 | 42967 | 47742 | 52516 | 57290 | 66838 | 76386 |

| K8-P700-DA | MIN | 15120 | 17640 | 20160 | 22680 | 25200 | 27720 | 30240 | 35280 | 40320 |

| MODEL | SPRING TORQUE | AIR SUPPLY PRESSURE | ||||||||

| MODEL | SPRING TORQUE | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 |

| K1-P200-SR2 | OPEN/CLOSED | 287 | 424 | 561 | 699 | 836 | 973 | 1110 | 1384 | 698 |

| K1-P200-SR2 | MIN | 110 | 182 | 254 | 327 | 399 | 472 | 544 | 689 | 325 |

| K1-P200-SR2 | CLOSE | 125 | 262 | 399 | 536 | 673 | 840 | 948 | 1222 | 536 |

| K2-P250-SR2 | OPEN/CLOSED | 548 | 811 | 1074 | 1336 | 1599 | 1861 | 2124 | 2649 | 1339 |

| K2-P250-SR2 | MIN | 209 | 348 | 486 | 625 | 764 | 902 | 1041 | 1318 | 623 |

| K2-P250-SR2 | CLOSE | 237 | 499 | 762 | 1025 | 1287 | 1550 | 1813 | 2338 | 1028 |

| K3-P300-SR2 | OPEN/CLOSED | 962 | 1424 | 1885 | 2347 | 2808 | 3270 | 3731 | 4654 | 2355 |

| K3-P300-SR2 | MIN | 366 | 610 | 854 | 1097 | 1341 | 1585 | 1828 | 2315 | 1095 |

| K3-P300-SR2 | CLOSE | 414 | 876 | 1337 | 1799 | 2261 | 2722 | 3184 | 4107 | 1807 |

| K4-P350-SR2 | OPEN/CLOSED | 1574 | 2329 | 3085 | 3840 | 4595 | 5351 | 6106 | 7617 | 3856 |

| K4-P350-SR2 | MIN | 599 | 998 | 1397 | 1795 | 2194 | 2593 | 2992 | 3789 | 1793 |

| K4-P350-SR2 | CLOSE | 677 | 1432 | 2188 | 2943 | 3699 | 4454 | 5210 | 6721 | 2959 |

| K5-P400-SR2 | OPEN/CLOSED | 2065 | 3056 | 4048 | 5040 | 6031 | 7023 | 8014 | 9997 | 5062 |

| K5-P400-SR2 | MIN | 786 | 1309 | 1833 | 2356 | 2880 | 3403 | 3926 | 4973 | 2354 |

| K5-P400-SR2 | CLOSE | 888 | 1879 | 2871 | 3862 | 4854 | 5845 | 6837 | 8820 | 3884 |

| K6-P500-SR2 | OPEN/CLOSED | 3979 | 5890 | 7801 | 9713 | 11624 | 13535 | 15447 | 19269 | 9759 |

| K6-P500-SR2 | MIN | 1514 | 2523 | 3532 | 4541 | 5550 | 6559 | 7568 | 9585 | 4539 |

| K6-P500-SR2 | CLOSE | 1709 | 3621 | 5532 | 7443 | 9355 | 11266 | 13177 | 17000 | 7489 |

| K7-P600-SR2 | OPEN/CLOSED | 7286 | 10788 | 14289 | 17790 | 21291 | 24792 | 28293 | 35295 | 17877 |

| K7-P600-SR2 | MIN | 2773 | 4621 | 6469 | 8317 | 10165 | 12013 | 13861 | 17557 | 8315 |

| K7-P600-SR2 | CLOSE | 3129 | 6630 | 10131 | 13632 | 17133 | 20634 | 24135 | 31137 | 13720 |

| K8-P700-SR2 | OPEN/CLOSED | 9936 | 14710 | 19484 | 24258 | 29032 | 33806 | 38580 | 48129 | 24379 |

| K8-P700-SR2 | MIN | 3781 | 6301 | 8821 | 11341 | 13861 | 16381 | 18901 | 23941 | 11339 |

| K8-P700-SR2 | CLOSE | 4266 | 9040 | 13814 | 18588 | 23363 | 28137 | 32911 | 42459 | 18709 |

| MODEL | SPRING TORQUE | AIR SUPPLY PRESSURE | ||||||||

| MODEL | SPRING TORQUE | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 |

| K1AW-P200-DA | OPEN/CLOSED | 1646 | 1920 | 2195 | 2469 | 2743 | 3018 | 3292 | 3840 | 4389 |

| K1AW-P200-DA | MIN | 869 | 1014 | 1158 | 1303 | 1448 | 1593 | 1738 | 2027 | 2317 |

| K2AW-P250-DA | OPEN/CLOSED | 3152 | 3677 | 4203 | 4728 | 5253 | 5779 | 6304 | 7355 | 8405 |

| K2AW-P250-DA | MIN | 1664 | 1941 | 2218 | 2496 | 2773 | 3050 | 3327 | 3882 | 4437 |

| K3AW-P300-DA | OPEN/CLOSED | 5539 | 6462 | 7385 | 8308 | 9231 | 10154 | 11077 | 12923 | 14769 |

| K3AW-P300-DA | MIN | 2923 | 3411 | 3898 | 4385 | 4872 | 5360 | 5817 | 6821 | 7796 |

| K4AW-P350-DA | OPEN/CLOSED | 9066 | 10577 | 12088 | 13598 | 15109 | 16620 | 18131 | 21153 | 24175 |

| K4AW-P350-DA | MIN | 4785 | 5583 | 6380 | 7178 | 7975 | 8773 | 9570 | 11166 | 12761 |

| K5AW-P400-DA | OPEN/CLOSED | 11899 | 13882 | 15865 | 17848 | 19831 | 21814 | 23797 | 27764 | 31730 |

| K5AW-P400-DA | MIN | 6281 | 7327 | 8374 | 9421 | 10468 | 11514 | 12561 | 14655 | 16748 |

| K6AW-P500-DA | OPEN/CLOSED | 22936 | 26759 | 30581 | 34404 | 38227 | 42050 | 45872 | 53518 | 61163 |

| K6AW-P500-DA | MIN | 12107 | 14124 | 16142 | 18160 | 20178 | 22196 | 24213 | 28240 | 32284 |

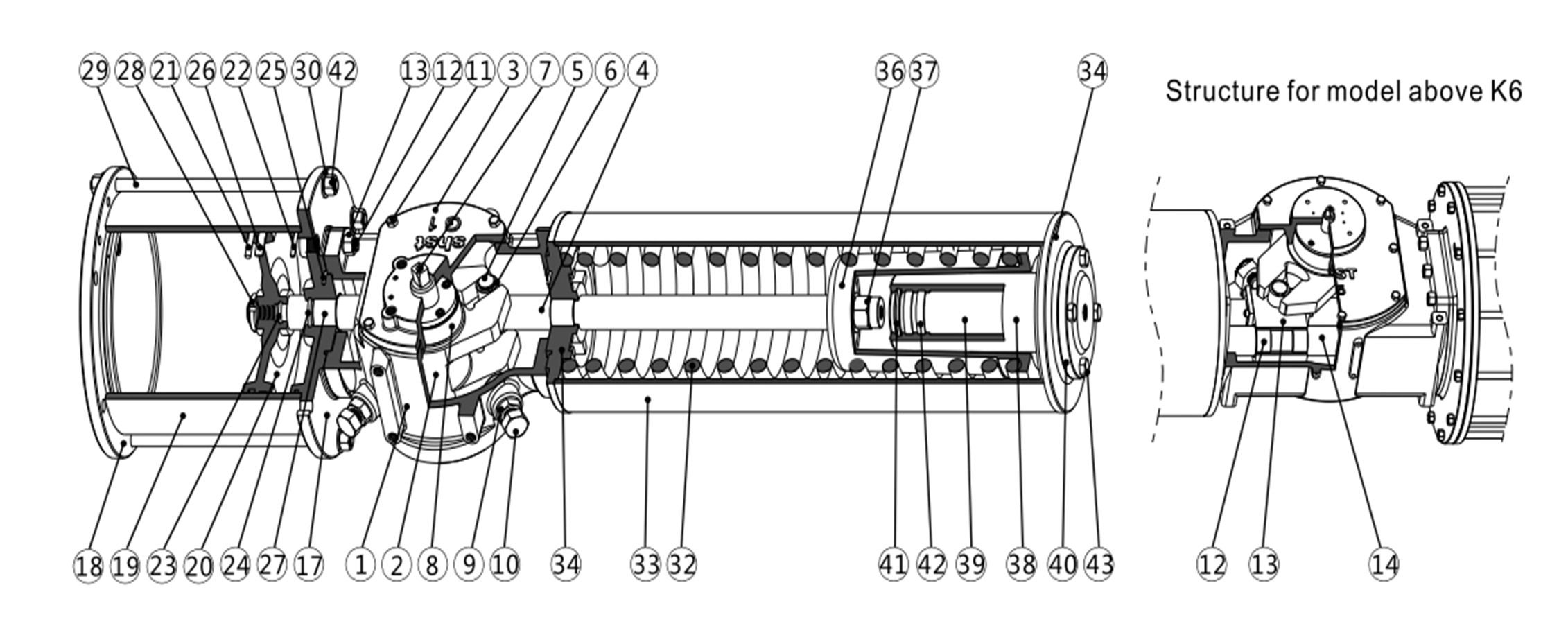

| NO. | PARTS | MATERIAL | NO. | PARTS | MATERIAL |

| 1 | BODY | DUCTILE CAST IRON | 23 | O RING | RUBBER |

| 2 | YORK | WCB | 24 | O RING | RUBBER |

| 3 | COVER | DUCTILE CAST IRON | 25 | O RING | RUBBER |

| 4 | PISTON ROD | CAST STEEL | 26 | GUIDE RING | COMPOSITE |

| 5 | PIN SHAFT | BEARING STEEL | 27 | LUBRICANT BEARING | COMPOSITE |

| 6 | ROLL SLEEVE | BEARING STEEL | 28 | LOCKING NUT | CARBON STEEL |

| 7 | OUTPUT SHAFT | CAST STEEL (CHROME PLATING) | 29 | DOUBLE STUD | CARBON STEEL |

| 8 | LUBRICANT BEARING | COMPOSITE | 30 | GASKET | CARBON STEEL |

| 9 | NUT | CAST STEEL | 31 | NUT | CARBON STEEL |

| 10 | ADJUST STUD | CAST STEEL | 32 | COMPRESSED SPRING | SPRING STEEL |

| 11 | HEXAGON STUD | CAST STEEL | 33 | SPRING STEEL | CARBON STEEL |

| 12 | DOUBLE STUD | CAST STEEL | 34 | SPRING SEAT | CARBON STEEL |

| 13 | NUT | CAST STEEL | 35 | WELDING FLANGE | CARBON STEEL |

| 14 | GUIDE ROD | CAST STEEL (CHROME PLATING) | 36 | SPRING SLEEVE | CARBON STEEL |

| 15 | SUPPORTER SLIDER | CAST STEEL | 37 | CAPTIVE NUT | CARBON STEEL |

| 16 | LUBRICANT BEARING | COMPOSITE | 38 | HYDRAULIC CYLINDER | CAST STEEL (CHROME PLATING) |

| 17 | INSIDE END CAP | DUCTILE CAST IRON | 39 | PLUG | CAST STEEL (CHROME PLATING) |

| 18 | OUTSIDE END CAP | DUCTILE CAST IRON | 40 | HYDRAULIC FLANGE | CAST STEEL |

| 19 | CYLINDER | CAST STEEL (CHROME PLATING) | 41 | SEALING RING | RUBBER |

| 20 | PISTON | DUCTILE CAST IRON | 42 | GUIDE RING | COMPOSITE |

| 21 | PISTON O RING | RUBBER | 43 | HEXAGON STUD | CAST STEEL |

| 22 | END CAP O RING | RUBBER |

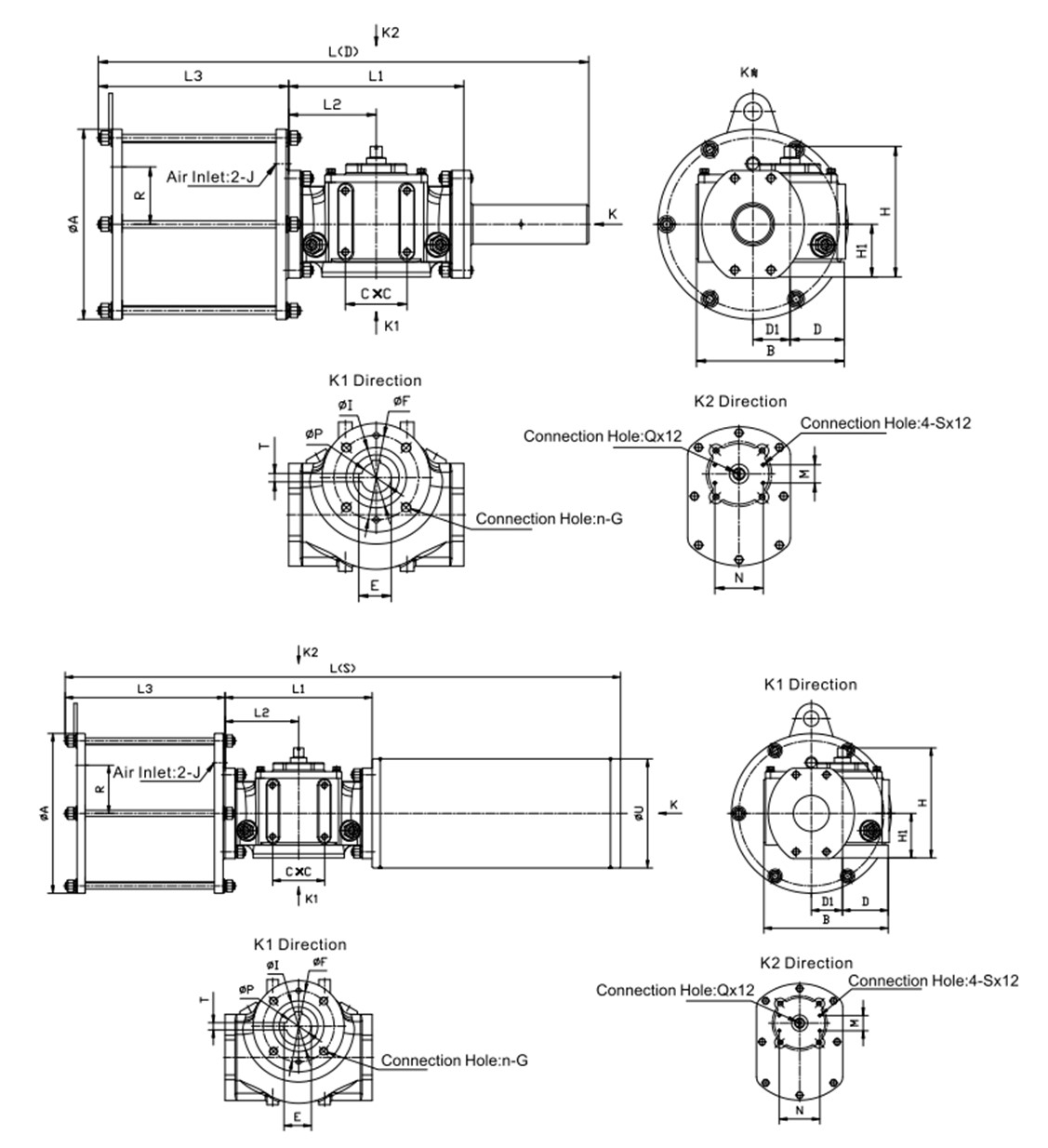

| MODEL | ISO5211 | L(D) | L(S) | L1 | L2 | L3 | H | H1 | A | B | C | D |

| K1-P200 | F10/F12 | 630 | 895 | 240 | 120 | 228 | 183 | 75 | 255 | 191 | 80X60 | 62.5 |

| K2-P250 | F14 | 812 | 1100 | 290 | 145 | 316 | 217 | 88 | 315 | 247 | 102 | 90 |

| K3-P300 | F16 | 917 | 1352 | 334 | 167 | 358 | 228 | 94.5 | 370 | 279 | 102 | 102.5 |

| K4-P350 | F25 | 1060 | 1518 | 390 | 195 | 403 | 265 | 108 | 420 | 355 | 102 | 150 |

| K5-P400 | F25 | 1060 | 1518 | 390 | 195 | 403 | 265 | 108 | 480 | 355 | 102 | 150 |

| K6-P500 | F30 | 1205 | 2270 | 476 | 238 | 565 | 308 | 130 | 600 | 430 | 102 | 175 |

| K7-P600 | F35 | 1580 | 2340 | 600 | 300 | 685 | 375 | 165 | 710 | 538 | 102 | 207.5 |

| K8-P700 | F35 | 1580 | 2340 | 600 | 300 | 685 | 375 | 165 | 830 | 538 | 102 | 207.5 |

| MODEL | D1 | E | F | n-G | I | J | M | N | P | Q | R | S | T | U |

| K1-P200 | 50 | 39.3 | 102/125 | 4-M10/M12 | 85 | ¼” | 30 | 80 | 36 | M6 | 76 | M5 | 10 | 166 |

| K2-P250 | 61.5 | 53.8 | 140 | 4-M16 | 100 | ½” | 30 | 80 | 50 | M6 | 95 | M5 | 14 | 202 |

| K3-P300 | 75 | 64.4 | 165 | 4-M20 | 130 | ½" | 30 | 80 | 60 | M6 | 118 | M5 | 18 | 244 |

| K4-P350 | 90 | 76.9 | 254 | 8-M16 | 200 | ½” | 30 | 80 | 72 | M6 | 145 | M5 | 20 | 297 |

| K5-P400 | 90 | 76.9 | 254 | 8-M16 | 200 | ¾” | 30 | 80 | 72 | M6 | 175 | M5 | 20 | 402 |

| K6-P500 | 110 | 127.4 | 298 | 8-M20 | 230 | 1” | 30 | 80 | 120 | M6 | 210 | M5 | 32 | 480 |

| K7-P600 | 140 | 170 | 356 | 8-M30 | 260 | 1” | 30 | 80/130 | 160 | M6 | 250 | M5 | 40 | 530 |

| K8-P700 | 140 | 170 | 356 | 8-M30 | 260 | 1.1/2” | 30 | 80/130 | 160 | M6 | 288 | M5 | 40 | 560 |

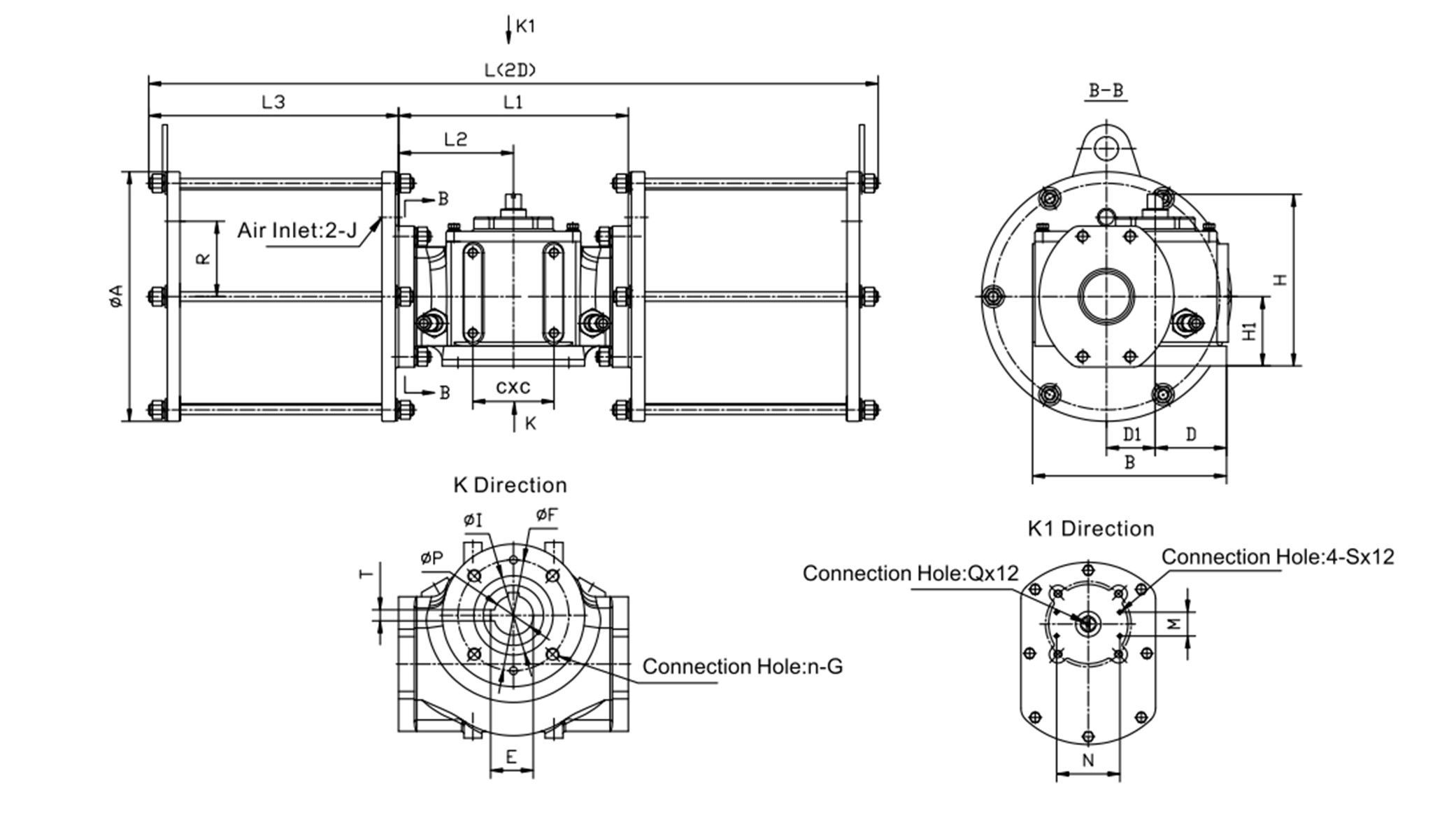

| MODEL | ISO5211 | L(2D) | L1 | L2 | L3 | H | H1 | A | B | C | D | D1 |

| K1AW-P200 | F10/F12 | 696 | 240 | 120 | 228 | 183 | 75 | 255 | 191 | 80X60 | 62.5 | 50 |

| K2AW-P250 | F14 | 922 | 290 | 145 | 316 | 217 | 88 | 315 | 247 | 102 | 90 | 61.5 |

| K3AW-P300 | F16 | 1050 | 334 | 167 | 358 | 228 | 94.5 | 370 | 279 | 102 | 102.5 | 75 |

| K4AW-P350 | F25 | 1196 | 390 | 195 | 403 | 265 | 108 | 420 | 355 | 102 | 150 | 90 |

| K5AW-P400 | F25 | 1196 | 390 | 195 | 403 | 265 | 108 | 480 | 355 | 102 | 150 | 90 |

| K6AW-P500 | F30 | 1476 | 476 | 238 | 500 | 308 | 130 | 610 | 430 | 102 | 175 | 110 |

| MODEL | E | F | n-G | I | J | M | N | P | Q | R | S | T |

| K1AW-P200 | 39.3 | 102/125 | 4-M10/M12 | 85 | ¼” | 30 | 80 | 36 | M6 | 76 | M5 | 10 |

| K2AW-P250 | 53.8 | 140 | 4-M16 | 100 | ½” | 30 | 80 | 50 | M6 | 95 | M5 | 14 |

| K3AW-P300 | 64.4 | 165 | 4-M20 | 130 | ½" | 30 | 80 | 60 | M6 | 118 | M5 | 18 |

| K4AW-P350 | 76.9 | 254 | 8-M16 | 200 | ½” | 30 | 80 | 72 | M6 | 145 | M5 | 20 |

| K5AW-P400 | 76.9 | 254 | 8-M16 | 200 | ¾” | 30 | 80 | 100 | M6 | 175 | M5 | 20 |

| K6AW-P500 | 127.4 | 298 | 8-M20 | 230 | 1” | 30 | 80 | 120 | M6 | 220 | M5 | 32 |

| MODEL | CYLINDER CAPACITY (L) | CYLINDER CAPACITY (L) | WORKING TIME (S) | WORKING TIME (S) | MAX. OPERATING PRESSURE (BAR) |

|---|---|---|---|---|---|

| MODEL | Inside | Outside | Open (Inside) | Close (Outside) | MAX. OPERATING PRESSURE (BAR) |

| K1-P200-DA | 3.2 | 3.3 | 2.0 | 2.0 | 0.8 |

| K2-P250-DA | 8.0 | 8.5 | 2.5 | 2.5 | 0.8 |

| K3-P300-DA | 13.5 | 15.0 | 3.0 | 3.0 | 0.8 |

| K4-P350-DA | 21.5 | 24.0 | 4.0 | 4.0 | 0.8 |

| K5-P400-DA | 34.0 | 38.5 | 5.0 | 5.0 | 0.8 |

| K6-P500-DA | 69.5 | 77.0 | 7.0 | 7.0 | 0.8 |

| K7-P600-DA | 123.0 | 129.0 | 8.0 | 8.0 | 0.8 |

| K8-P700-DA | 207.0 | 214.5 | 10.0 | 10.0 | 0.8 |

Spring Acting

| MODEL | CYLINDER CAPACITY (L) | CYLINDER CAPACITY (L) | WORKING TIME (S) | WORKING TIME (S) | MAX. OPERATING PRESSURE (BAR) |

|---|---|---|---|---|---|

| MODEL | Inside | Outside | Open (Inside) | Close (Outside) | MAX. OPERATING PRESSURE (BAR) |

| K1-P200-SR2 | 3.2 | - | 2.5 | 3.0 | 0.8 |

| K2-P250-SR2 | 8.0 | - | 3.0 | 3.5 | 0.8 |

| K3-P300-SR2 | 13.5 | - | 4.0 | 5.0 | 0.8 |

| K4-P350-SR2 | 21.5 | - | 5.0 | 6.0 | 0.8 |

| K5-P400-SR2 | 34.0 | - | 6.0 | 7.0 | 0.8 |

| K6-P500-SR2 | 69.5 | - | 9.0 | 10.0 | 0.8 |

| K7-P600-SR2 | 123.0 | - | 10.0 | 12.0 | 0.8 |

| K8-P700-SR2 | 207.0 | - | 12.0 | 14.0 | 0.8 |

Air Consumption Is Dependent On Air Supply Pressure, Open Close Stroke, Volume And Motion Times, Which Is Calculated As Following : L/Min = Air Volume (Opening Volume + Closing Volume)*Air Supply Pressure (Kpa)+101.3/101.3*Motion Times (Min.)

Option : Manual Device

In many

applications, the valve / actuator often need the hand wheel device.

In the condition of loss of air pressure, we can use the hand wheel to manually open

or

close the valve. KST has a variety of optional hand wheel products to meet customer

requirements, it includes open or closed mechanical hand wheel screw nut, the clutch

type mechanical hand wheel gear reducer, hydraulic wheel and the storage system.

| Hydraulic Manual Device | Declutch Hand wheel Device | Mechanical Hand wheel Device |

|---|---|---|

Hand wheel Device

|

|

|

Reach out for tailored solutions. Our team is ready to assist. Submit an inquiry and experience excellence in valve automation solutions.