PUM series intelligent multi turn actuator is applied in controlling various valves and other similar products, include butterfly valve, ball valve, gate valve, control valve and etc. It is widely applied in petroleum, chemical, water treatment, shipping, paper making, power plants, heating, building automation and other industries. PUM series multi turn actuator combine the characteristic of intelligent and reliable, and expand richer application based on basic modular product. It can meet various kinds of working conditions. There are different PUM valve gear boxes can be configured which greatly expanded the torque range or turn the multi-turn actuator into quarter turn actuator, linear actuator to meet the different requirements.

The main shell if made of aluminium, lighter weight. The surface coating of epoxy resin, and go through the 12 step of coating protective treatment, with high corrosion resistance, the protection grade is IP67, NEMA4 and 6.

Fully enclosed squirrel-cage motor, small size, large torque, and small inertia force, insulation class F, build in thermal protection switch to avoid damaging the motor.

Using oil immersed type, it can provide excellent lubrication and cooling in case of high strength, large temperature different and high torque, the oil is more stable.

Terminal box, which is double sealing and separate enclosure protection, assure the sealing integrity of the electronic component if open the box cover to make the on-site wiring. The motor and the controls are connected by 29 contacts.

Traditional potentiometer is eliminated, and adopt magnetic induction absolute encoder to provide position accuracy. It can record the precise valve position without battery if actuator power off.

The setting and diagnostic of the actuator can be processed via sealing display screen, without opening the housing. The valid distance between the setting tools and display screen is about 1-1.5m.

Local control switches and locking type selector switch local/stop/remote are magnetic switches, controlled by magnetic reed, thus assure the damp proof sealing inside of the actuator.

The handle is designed to ensures safe, reliable, labor-saving and small. When the power outage, press the red button in the middle of handwheel to make motor and actuator disconnected, and start manual operation. Because of the automatic clutch between the motor and the operating shaft, it is easy to turn to manual operation even if the actuator at the maximum torque . After starting the motor, automatically breaks away from manual operation. When performing motor operation handwheel does not work .(Note: In the situation of no electricity, the electric actuator will remain permanently manual mode).

It is used to control temperature and remain the internal electrical components dry, it can avoid the moisture condensation inside the actuator because of the change of the temperature and weather.

Providing overload protection, it can shut down the power automatically when jamming to avoid damaging valves and actuators, torque is adjustable within a certain range.

Precision worm mechanism can efficiently transfer large torque, high efficiency, low noise (max 50 dB), long life, and have self-locking function to prevent the inversion, transmission part is stable and reliable.

The bolts will attach to the case and not fall off when removing the shell, external screws are made of 304 stainless steel.

The bottom mounting dimensions conform to international standard ISO5210,the drive sleeve can be removed for processing as needed. It can be installed vertically and horizontally.

The control circuit in line with single-phase or three-phase power supply standard, circuit layout is compact and reasonable , (It can be designed according to customer requirements).

Electrical actuator with Linear Thrust Element / Gear Box Torque : 5KN-217KN Suitable for Globe valve and Gate Valve.

| No. | Combination Torque (Nm) | Electric Actuator (Torque) | Default Speed R/Min. | Default Ratio | Open Time (s) |

|---|---|---|---|---|---|

| 1 | 2500 | Contact the manufacturers | 24 | 122:1 | 76s |

| 2 | 3500 | 24 | 122:1 | 76s | |

| 3 | 4500 | 24 | 132:1 | 83s | |

| 4 | 6500 | 24 | 150:1 | 94s | |

| 5 | 8500 | 24 | 150:1 | 94s | |

| 6 | 10000 | 24 | 150:1 | 94s | |

| 7 | 13000 | 24 | 160:1 | 100s | |

| 8 | 16000 | 24 | 160:1 | 100s | |

| 9 | 22000 | 24 | 153:1 | 96s | |

| 10 | 26000 | 24 | 215:1 | 135s | |

| 11 | 35000 | 24 | 255:1 | 160s | |

| 12 | 40000 | 24 | 340:1 | 212s | |

| 13 | 50000 | 24 | 360:1 | 225s |

Due to the inertia effect and wear of the driving shaft sleeves. It is recommended not to run at too high speeds when directly installed on a gate valve. The rated torque is the maximum torque set in two directions. The maximum torque is 1.4 to 2 times that, depending on the actuator’s speed and voltage. If you require the use of maximum torque when exceeding 20% of the valve stroke, please contact us.

Three phase 380VAC – adjustable type with switch and trigger frequency of less than 600 times.

|

50Hz RPM

NO Model |

18 | 24 | 36 | 48 | 72 | 96 | 144 |

|---|---|---|---|---|---|---|---|

| PUM10 | 100 | 90 | 80 | 70 | 50 | 40 | |

| PUM15 | 150 | 130 | 120 | 100 | 70 | 60 | |

| PUM20 | 200 | 200 | 180 | 170 | 150 | 100 | |

| PUM30 | 300 | 280 | 250 | 200 | 170 | 120 | |

| PUM40 | 400 | 350 | 300 | 250 | 230 | 150 | |

| PUM50 | 500 | 450 | 400 | 350 | 300 | 200 | |

| PUM60 | 100 | 90 | 80 | 70 | 50 | 40 | |

| PUM80 | 800 | 750 | 650 | 600 | 480 | 350 | |

| PUM100 | 1000 | 850 | 700 | 650 | 550 | 420 | |

| PUM150 | 1500 | 1300 | 1000 | 900 | 750 | 650 | |

| PUM200 | 2000 | 1700 | 1400 | 1200 | 1000 | 850 | |

| PUM300 | 3000 | 2000 | 1800 | 1600 | 1450 | 1350 | |

Three phase 380VAC – adjustable type with trigger frequency of less 600-1200 times.

|

50Hz RPM

NO Model |

18 | 24 | 36 | 48 | 72 | 96 | 144 |

|---|---|---|---|---|---|---|---|

| PUM10 | 100 | 90 | 80 | 70 | 50 | 40 | |

| PUM15 | 150 | 130 | 120 | 100 | 70 | 60 | |

| PUM20 | 200 | 200 | 180 | 170 | 150 | 100 | |

| PUM30 | 300 | 280 | 250 | 200 | 170 | 120 | |

| PUM40 | 400 | 350 | 300 | 250 | 230 | 150 | |

| PUM50 | 500 | 450 | 400 | 350 | 300 | 200 | |

| PUM60 | 100 | 90 | 80 | 70 | 50 | 40 | |

| PUM80 | 800 | 750 | 650 | 600 | 480 | 350 | |

| PUM100 | 1000 | 850 | 700 | 650 | 550 | 420 | |

| PUM150 | 1500 | 1300 | 1000 | 900 | 750 | 650 | |

| PUM200 | 2000 | 1700 | 1400 | 1200 | 1000 | 850 | |

| PUM300 | 3000 | 2000 | 1800 | 1600 | 1450 | 1350 | |

Single phase 220VAC – switch type

|

50Hz RPM

NO Model |

18 | 24 | 36 | 48 | 72 | 96 | 144 |

|---|---|---|---|---|---|---|---|

| PUM10 | 100 | 90 | 80 | 70 | 50 | 40 | |

| PUM40 | 150 | 130 | 120 | 100 | 70 | 60 | |

| PUM60 | 200 | 200 | 180 | 170 | 150 | 100 | |

| PUM100 | 300 | 280 | 250 | 200 | 170 | 120 | |

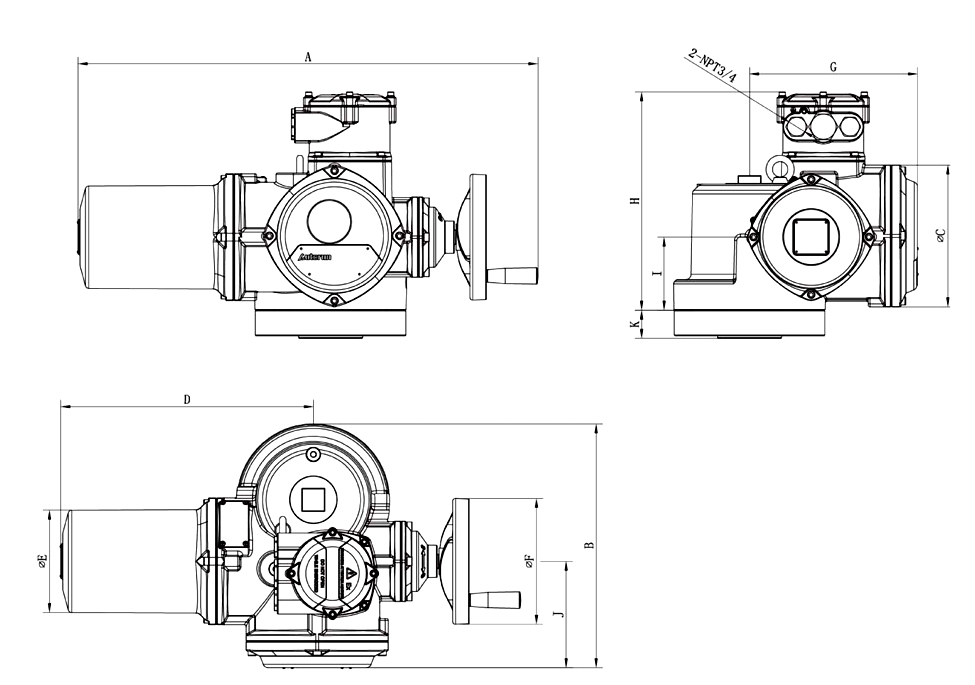

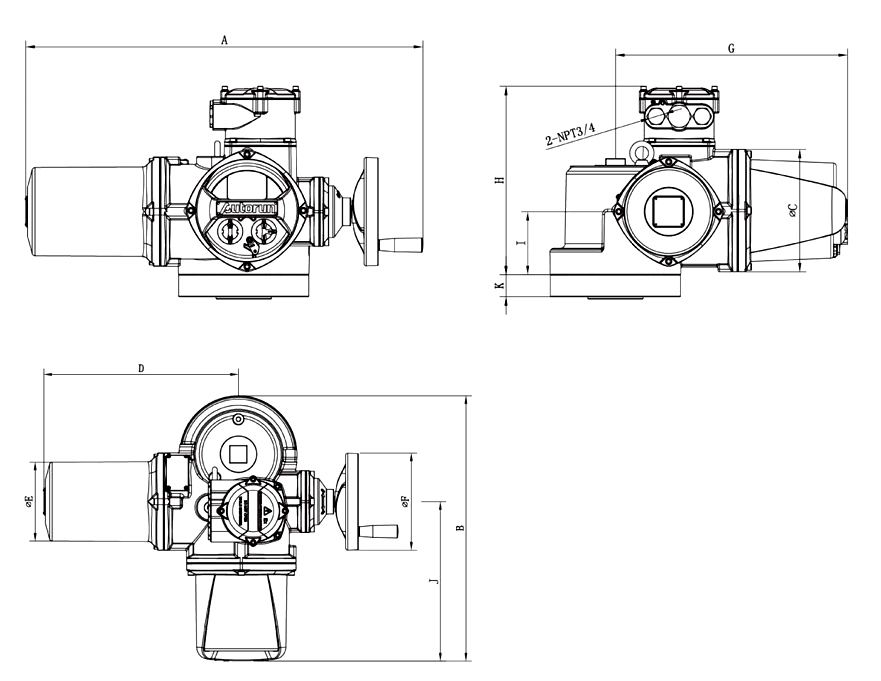

| Model | A | B | C | D | E | F | G | H | I | J |

K

Z TYPE FLANGE T TYPE FLANGE |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PUM10 | 591 | 453 | 222 | 297 | 102 | 200 | 220 | 325 | 107 | 160 | 40 | 60 |

| PUM15 | 591 | 453 | 222 | 297 | 102 | 200 | 220 | 325 | 107 | 160 | 40 | 60 |

| PUM20 | 668 | 491 | 222 | 355 | 131 | 200 | 236 | 335 | 108 | 160 | 40 | 60 |

| PUM30 | 668 | 491 | 222 | 355 | 131 | 200 | 236 | 335 | 108 | 160 | 40 | 60 |

| PUM40 | 668 | 491 | 222 | 355 | 131 | 200 | 236 | 335 | 108 | 160 | 40 | 60 |

| PUM50 | 718 | 538 | 222 | 394 | 160 | 200 | 262 | 341 | 114 | 166 | 40 | 60 |

| PUM60 | 718 | 538 | 222 | 394 | 160 | 200 | 262 | 341 | 114 | 166 | 40 | 60 |

| PUM80 | 718 | 538 | 222 | 394 | 160 | 200 | 262 | 341 | 114 | 166 | 40 | 60 |

| PUM100 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 178 | 50 | 120 |

| PUM150 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 178 | 50 | 120 |

| PUM200 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 178 | 50 | 120 |

| PUM300 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 178 | 50 | 120 |

| Model | A | B | C | D | E | F | G | H | I | J |

K

Z TYPE FLANGE T TYPE FLANGE |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PUM10 | 591 | 453 | 222 | 297 | 102 | 200 | 220 | 325 | 107 | 318 | 40 | 60 |

| PUM15 | 591 | 453 | 222 | 297 | 102 | 200 | 220 | 325 | 107 | 318 | 40 | 60 |

| PUM20 | 668 | 491 | 222 | 355 | 131 | 200 | 236 | 335 | 108 | 318 | 40 | 60 |

| PUM30 | 668 | 491 | 222 | 355 | 131 | 200 | 236 | 335 | 108 | 318 | 40 | 60 |

| PUM40 | 668 | 491 | 222 | 355 | 131 | 200 | 236 | 335 | 108 | 318 | 40 | 60 |

| PUM50 | 718 | 538 | 222 | 394 | 160 | 200 | 262 | 341 | 114 | 324 | 40 | 60 |

| PUM60 | 718 | 538 | 222 | 394 | 160 | 200 | 262 | 341 | 114 | 324 | 40 | 60 |

| PUM80 | 718 | 538 | 222 | 394 | 160 | 200 | 262 | 341 | 114 | 324 | 40 | 60 |

| PUM100 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 335 | 50 | 120 |

| PUM150 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 335 | 50 | 120 |

| PUM200 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 335 | 50 | 120 |

| PUM300 | 871 | 438 | 222 | 515 | 230 | 250 | 298 | 345 | 119 | 335 | 50 | 120 |

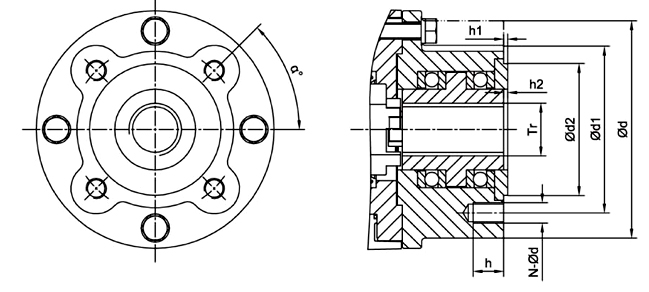

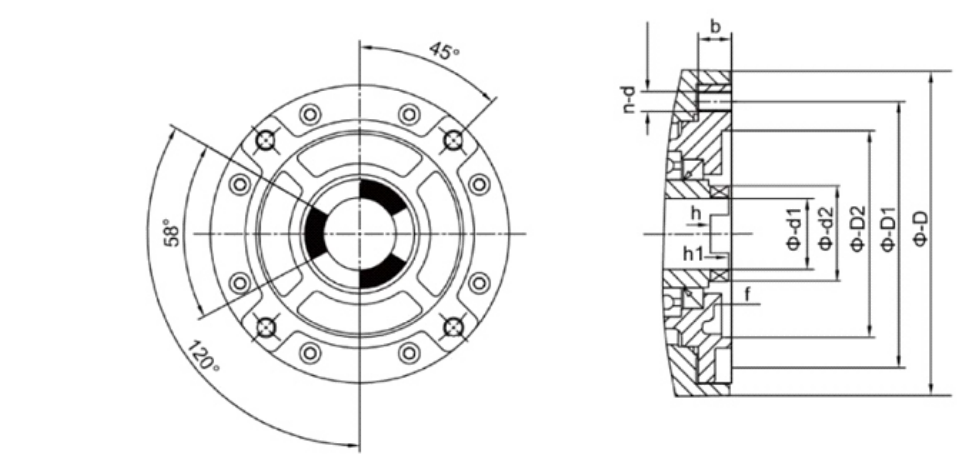

| No Model | BASE NO | ØD | Ød1 | ØD2 | Ød1 | Ød2 | f | h | h1 | n-d | B |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PUM10/15 | JB2 | 145 | 120 | 90 | 30 | 45 | 5 | 8 | 2 | 4-M10 | 15 |

| PUM20/30/40 | JB3 | 185 | 160 | 125 | 43 | 58 | 5 | 10 | 2 | 4-M12 | 15 |

| PUM 50/60/80 | JB4 | 225 | 195 | 150 | 50 | 72 | 5 | 12 | 2 | 4-M16 | 30 |

| PUM 100/150 | F25 | 338 | 254 | 215 | 82 | 108 | 5 | 16 | 2 | 4-M16 | 25 |

| PUM 200/300 | F30 | 338 | 298 | 215 | 82 | 108 | 5 | 16 | 2 | 8-M20 | 30 |

Electrical actuator with Linear Thrust Element / Gear Box Torque : 5KN-217KN Suitable for Globe valve and Gate Valve.

| No. | Max. Thrust (N) | Standard Stroke (mm) | Customized Stroke (mm) |

|---|---|---|---|

| 1 | 6400 | 10-60 | 60-100 |

| 2 | 10000 | 10-60 | 60-100 |

| 3 | 16000 | 10-60 | 60-100 |

| 4 | 25000 | 10-60 | 60-100 |

| 5 | 35000 | 10-60 | 60-100 |

| 6 | 45000 | 10-60 | 60-100 |

| 7 | 65000 | 10-60 | 60-100 |

| General Parameter | |

|---|---|

| Torque Range | 60-800Nm Direct output |

| Rotate Speed | 18-144 (rpm) |

| Environment Temperature | -20OC TO 70OC |

| Vibration Leve | JB/T8219 |

| Noise Level | Less than 70dB within one meter |

| Electrical Interface | 2 X NPT3/4, Standby 1XNPT 3/4 (Contact Pneutork for customization) |

| IP Grade | IP67, IP 68 Optional (15 meters underwater for 72 hours no leakage) |

| Connection | JB2920 (Three Jaw Type) or ISO 5210 (Thrust Type, Torque Type) |

| Technical Parameters | |

| Motor | Class F, with heat Protector 135ºc |

| Duty | ON/OFF, S1-15min, No more than 600 start per hour |

| Voltage |

3PH : AC380V (10%) : 50HZ (5%) 3PH 4 wires

Optional : 220VAC 415V (other voltage customize) |

| Bus Type | NA |

| On/off – Input | ON/OFF control, Contact Inside support 5A@250Vac |

| - Output | Full open / Full Close dry contact |

|

Passive contact of Opening Overtorque / Closing Overtorque

Optional : half modulating with potentiometer |

|

| Control Mode | Pointer Opening Dial |

| Display Mode | N/A |

| Manu Control | N/A |

| Local Control | N/A |

| Data Recording Intelligent Diagnostics | Moisture proof heater (moisture proof device) |

| Other Functions |

Motor overheat protection

Torque Bypass Explosion proof IR remote Control |

| General Parameter | |

|---|---|

| Torque Range | 60-800Nm Direct output |

| Rotate Speed | 18-144 (rpm) |

| Environment Temperature | -20ºC TO 70ºC |

| Vibration Level | JB/T8219 |

| Noise Level | Less than 70dB within one meter |

| Electrical Interface | 2 X NPT3/4, Standby 1XNPT 3/4 (Contact Pneutork for customization) |

| IP Grade | IP67, IP 68 Optional (15 meters underwater for 72 hours no leakage) |

| Connection | JB2920 (Three Jaw Type) or ISO 5210 (Thrust Type, Torque Type) |

| Technical Parameters | |

| Motor | Class F, with heat Protector 135Oc |

| Duty |

ON/OFF, S1-15min, No more than 600 start per hour

Modulating: S4-50% No more than 600 triggers per hour Optional: 1200 times per hour |

| Voltage |

3PH: AC380V (10%) : 50HZ (5%) 3PH 4 wires

Optional: 220VAC 415V (other voltage customize) |

| Bus Type | Optional : Modbus : Profibus | On/off Details |

| Input | ON/OFF signal (passive dry contact, active 24V active 220V, Inching / hold switchable) |

| On/off - Output |

Six non – holding relay contact output (five state relay + one integrated

faulty relay)

One way analog output feedback: 4-20mA, Output impedance ≤750 (standard 4-20mA, optional 0-10V, 2-10V, others) customizable |

Modulating |

| Input |

ON/OFF signal (passive dry contact, active 24V active 220V, Inching / hold

switchable)

Analog signal : 4-20mA, input impedance ≤100 (Optional 0-10V, 2~10V, others customizable) |

| Output |

Six non-holding relay contact output (five state relay + one integrated

fault relay)

One way analog output feedback : 4-20mA, Output impedance ≤750 (Standard 4-20mA, Optional 0-10V, 2-10V, Others) customizable |

| Dead Zone | 0.3~9.9% adjustable within the whole stroke |

| Reverse Signal | SSupport |

| Default Mode Setting | Support | Control Mode |

| Display Mode |

Fourth – order grey-scale LCD opening indicator

Open/Close/Remote/Fault indicator (Figures show opening percentage and torque percentage) |

| Manu Control |

Non-open cover setting (menu setting via remote control or button)

Configuration setting (such as valve position, maximum opening, maximum torque etc.) |

| Local Control |

Non-Invasive local control button (valve operating/valve

closing/stop)

Non-invasive local control button (close control/remote control/forbidden) |

| Data recording intelligent Diagnosis | Infrared remote control with menu for fault diagnosis analysis |

| Other Functions | Automatic calibration of phase sequence (three-phase power supply only) |

| Torque setting and protection - Motor heat protection – Torque Bypass | |

| Moisture – proof heater (moisture-proof device) ESD can be set : Fully on, Fully off, and Maintain position | |

| Launching record Opening Trend Record | |

| Event Log Operating Time Average Torque | |

| Explosion proof IR Remote Control | |

Reach out for tailored solutions. Our team is ready to assist. Submit an inquiry and experience excellence in valve automation solutions.